Home » Events » Technical Info » EN Standards

En10217-2 P235GH

En10217-2 P235GH Welding Steel Pipe/Tube

En10217-2 P235GH welding pipe/tube is widely used in piling project, heat-supply project, conveying drinking water, drainage, coal gas, fuel gas, mine slurry and other low/middle pressure fluids. P235GH welding pipe/tube package: 1. bundle packing or in bulk, 2. beveled or plain ends as per buyer's request, 3. marks: as per client's request, 4. metal or plastic protecting caps at pipe ends.

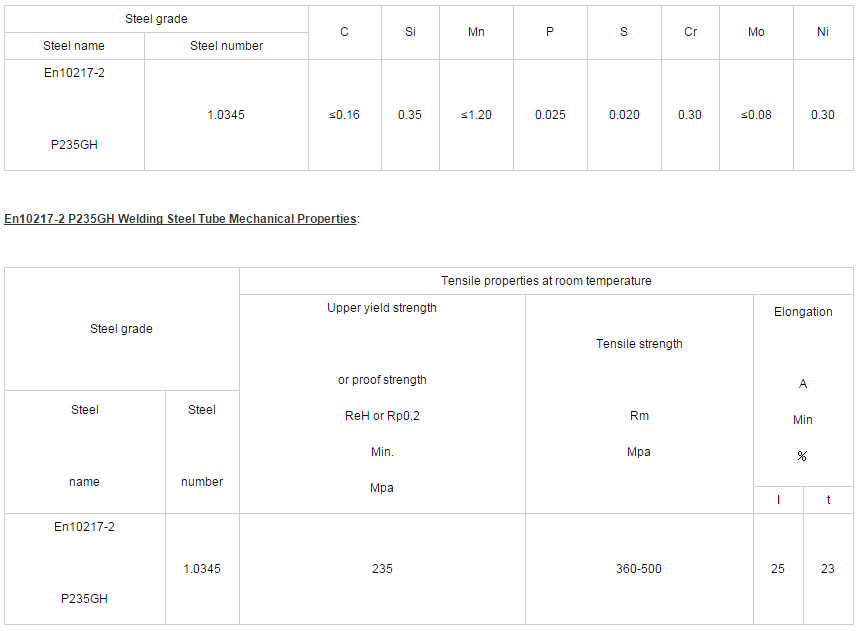

En10217-2 P235GH Welding Steel Pipe Chemical Composition Analysis:

En10217-2 P235GH Welding Steel Pipe Appearance

1. The P235GH tubes shall be free from external and internal surface defects that can be detected by visual examination.

2. The P235GH internal and external surface finish of the tubes shall be typical of the manufacturing process and, where applicable, the P235GH heat treatment employed. Normally the P235GH finish and surface condition shall be such that any surface imperfections requiring dressing can be identified.

3. It shall be permissible to dress, only by grinding or machining, surface imperfections provided that after doing so, the P235GH wall thickness in the dressed area is not less than the specified minimum wall thickness. All dressed areas shall blend smoothly into the contour of the P235GH tube.

4. Any P235GH surface imperfection, which is demonstrated to be deeper than 5 % of the wall thickness T or 3mm whichever is the smaller, shall be dressed. This requirement does not apply to surface imperfection with a depth equal or less 0,3 mm

5. P235GH Surface imperfections which encroach on the specified minimum wall thickness shall be considered defects and tubes containing these shall be deemed not to conform to this Part of EN 10217.

6. Repairs to the P235GH weld seam are not permitted