ASTM A53 GR A

ASTM A53 GR A welded steel pipe/tube

ASTM A53 grade A specification for General Requirements for Specialized Carbon and Alloy Steel Pipe.

ASTM A53 grade A alloy pipe uses in steam, water, gas, and air lines. It is suitable for welding, and suitable for forming operations involving coiling, bending, and flanging.

The size of A53 Grade A carbon steel pipe/tube

ERW; outer diameter:21.3-660mm thickness:6-25mm

LSAW; outer diameter:325-1524mm thickness:6-50mm

SSAW: outer diameter:219-3200mm thickness:5-25mm

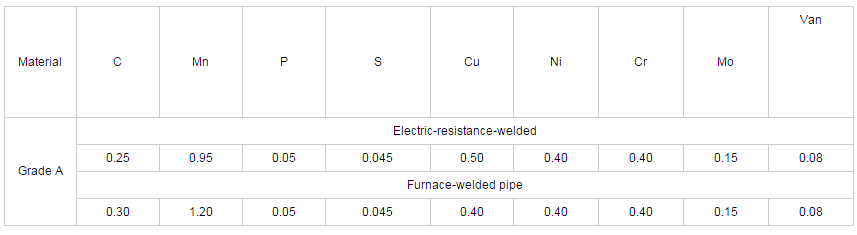

A53 Grade A material chemical composition

Electric-Resistance-Welded Pipe—Pipe produced in single lengths, or in multiple lengths from coiled skelp and subsequently cut into individual lengths, having a longitudinal butt joint wherein coalescence is produced by the heat obtained from resistance of the pipe to the flow of electric current in a circuit of which the pipe is a part, and by the application of pressure.

Furnace-Butt-Welded Pipe, Continuous Welded Pipe—Pipe produced in multiple lengths from coiled skelp and subsequently cut into individual lengths, having its longitudinal butt joint forge welded by the mechanical pressure developed in rolling the hot-formed skelp through a set of round pass welding rolls.

ASTM A53 Grade A weld alloy pipe/tube mechanical properties

| Material | Tensile strength,min,psi(mpa) | Yield strength, min, psi [Mpa] | Elongation in 2 in. or 50 mm |

| Grade A | 48 000 [330] | 30 000 [205] | A,B |

A The minimum elongation in 2 in. [50 mm] shall be that determined by the

following equation:

e5625 000 [1940]A0.2/U0.9

where:

e = minimum elongation in 2 in. or 50 mm in percent, rounded to the nearest

percent,

A = the lesser of 0.75 in.2[500 mm2] and the cross-sectional area of the

tension test specimen, calculated using the specified outside diameter of

the pipe, or the nominal width of the tension test specimen and the

specified wall thickness of the pipe, with the calculated value rounded to

the nearest 0.01 in.2[1 mm2], and

U = specified minimum tensile strength, psi [MPa].