Projects

K55 BTC R3 Casing for Djen Client

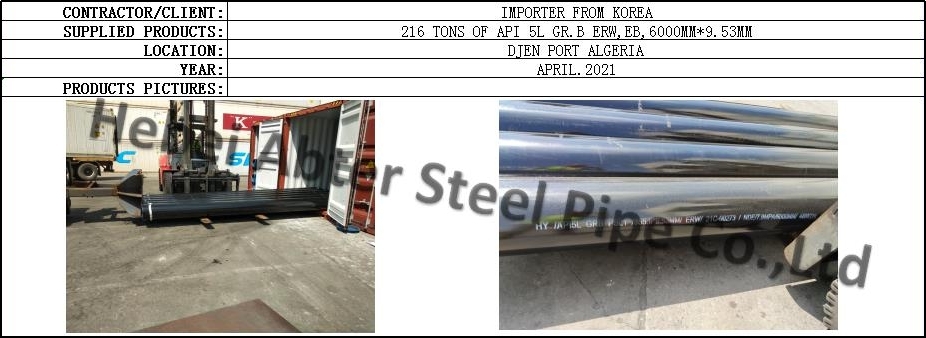

API 5L GRB ERW Steel Pipe for Korea Client

ERW Steel Pipe for Dubai Client

API 5L X65 SMLS Pipe for Korea Client

A106/API 5LB/ API 5L X 42 SMLS Pipe for Korea Client

API 5L GRB SMLS Pipeline for Vietam

ALLOY STEEL ECONOMISER Tubes for Australia Client

API 5L GR.B SMLS Pipe for South Africa Client

ASTM A106 SMLS Pipe for South Africa Client

ASTM A106 GR.B SMLS Pipe for Turkey Client

API 5L SMLS Pipe for UAE Client

K55&N80-1 Casing Pipe for Poland Client

SMLS With Threading&Coupling for Jordan Client

JIS G3461 STB410 Pipe for Durban Client

ERW&Pipe Fittings with Internal Mortar Cement for Singapore Client

ASTM A106 pipe for Durban Client

16Mo3 Alloy Tube for Durban Client

3LPE Coated Pipe for Qatar Client

K55 Casing Pipe for Algeria client

Galvanized SSAW for Saudi Arabia Client

N80 Casing Pipe for Poland Client

API 5L X42 SMLS Pipe for Thailand Client

API 5L Pipe for Pakistan Client

API 5L Pipe for South Africa Client

API 5L Pipe for South Africa Client

Pipeline for JG SUMMIT OLEFINS

API 5L Pipeline for CBI in Thailand

API 5CT Casing for Algeria Client

API 5L X42 Pipeline for UAE client

ASTM A179 Tube for Durban Client

Internal and external burr of ERW steel tube.Due to the continuous improvement and perfection of the structure of the burr system and the cutting tool, the burr of the large and medium caliber steel pipe has been better treated.The burr can be controlled in -0.2mm ~ 0.5mm.Physical seamless refers to the difference between the metallographic structure inside the weld and the base metal, which results in the decrease of the mechanical properties of the weld area. It is necessary to take measures to make it uniform and consistent.The high frequency welding thermal process of ERW steel tube causes the temperature gradient near the edge of the tube, and forms the characteristic areas such as melting zone, semi-melting zone, superheated structure, normalizing zone, non-normalizing zone and refiring zone.Among them, the austenite grains in the overheated area grow rapidly due to the welding temperature above 1000℃, and the hard and brittle coarse grain phase will be formed under the cooling condition. In addition, the existence of temperature gradient will produce welding stress.In this way, the mechanical properties of the weld area are lower than that of the base metal. Physical seamless is to heat the weld area to AC3(927℃) through the local conventional heat treatment process of the weld area, namely the use of intermediate frequency induction heating device, and then carry out the air cooling process with a length of 60m and a speed of 20m/ min, and then water cooling when necessary.The application of this method can eliminate stress, soften and refine microstructure, and improve the comprehensive mechanical properties of heat-affected zone.At present, advanced ERW units in the world have generally adopted this method to treat the welding seam, and good results have been obtained.In addition, the weld coefficient of the ERW steel tube reached 1, which realized the match between the weld area structure and the base metal.

Due to the use of hot rolled coil as raw material, the wall thickness of ERW steel pipe can be controlled within ±0.2mm or so, the two ends of the steel pipe can be repaired and beveled according to APL standard or GB/T9711.1 standard, and the delivery of fixed length and so on.In recent years, various pipeline engineering and gas companies have widely adopted ERW steel pipe as the main pipe of urban pipeline network.