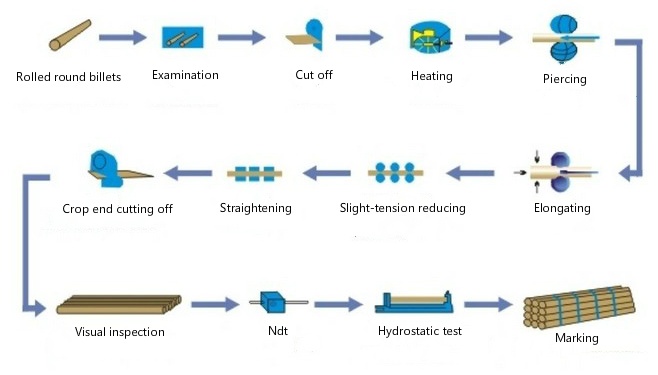

Hot Rolled Process for Seamless Steel Pipe

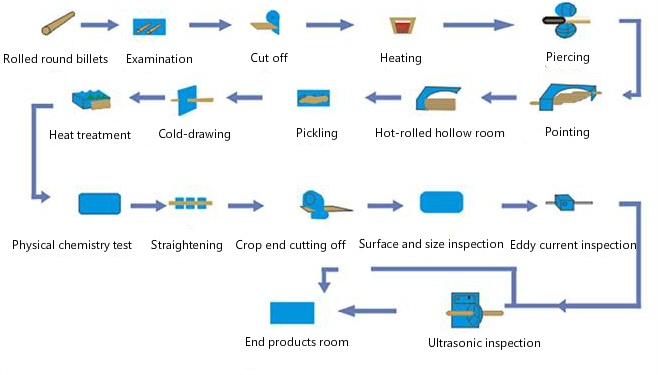

Cold Drawn Process for Seamless Steel Pipe

The process of cold drawing is a procedure by which steel profiles are formed in order to achieve complex cross sections of excellent precision in these cold drawn steel shapes. After careful pre-treatment and de-scaling, the special profile bars are drawn through a forming die. This operation can be repeated up to three or four times. Cold drawing of hot rolled and hot extruded special pre-shape steel profiles tightens the cross-sectional tolerances, thus leading to significant improvement in dimensional accuracy and surface quality. Cold drawn steel special profiles offer the same precision achieved by machining but without the waste.

During the production of special hot rolled steel profiles by hot rolling the input billet or slab is formed into lengths up to 70 m using two oppositely rotating cylindrical rolls. The hot rolled steel shapes of this forming technique are used in a multitude of industrial applications. Hot rolled special profiles offer innovative solutions whether it be for automotive, materials handling, railroad or thicker flange and web thickness structural steel shapes use. Finished hot rolled steel shapes are roller straightened and sheared into production lengths or sawn into fixed lengths according to customer wishes.

During hot extrusion a round steel billet is pre-heated and, after leaving the furnace, is pushed through a forming die into a profile bar using a ram with an extrusion force of 2,200 ton. Hot extrusion offers substantial advantages in comparison to hot rolling forging or machining. Hot extrusion can be used to make complex profile shapes even using metals which are difficult to form. In addition, small lot sizes can be produced economically.

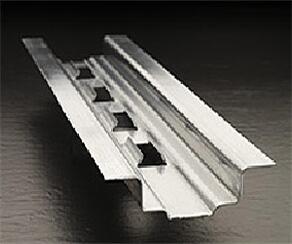

Cold Rolling Cold Forming Roll Forming

Cold Rolling Cold Forming Roll Forming

Roll forming can be described as a continuous bending operation done at room temperature in which sheet or strip metal is plastically deformed along a linear axis. Tandem sets of rolls (known as roll stations) shape the metal stock in a series of progressive stages until the desired cross-sectional configuration is obtained by cold rolling.Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce multiple length parts from the same set of tooling. Virtually any material that can be cold formed by sheet forming techniques can be roll formed.